Structural Integrity

Our shower pan is a mere 7/8″ thick which allows it to be installed without cutting, notching, or lowering any of the supports below the shower. Regardless if your home is constructed using I-Joists, Engineered Trusses or Traditional Joists or on a concrete slab, the VIM Level Entry Shower System™ is the best choice for the job

Ways to INstall our Shower

WOOD FLOOR INSTALLATION

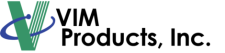

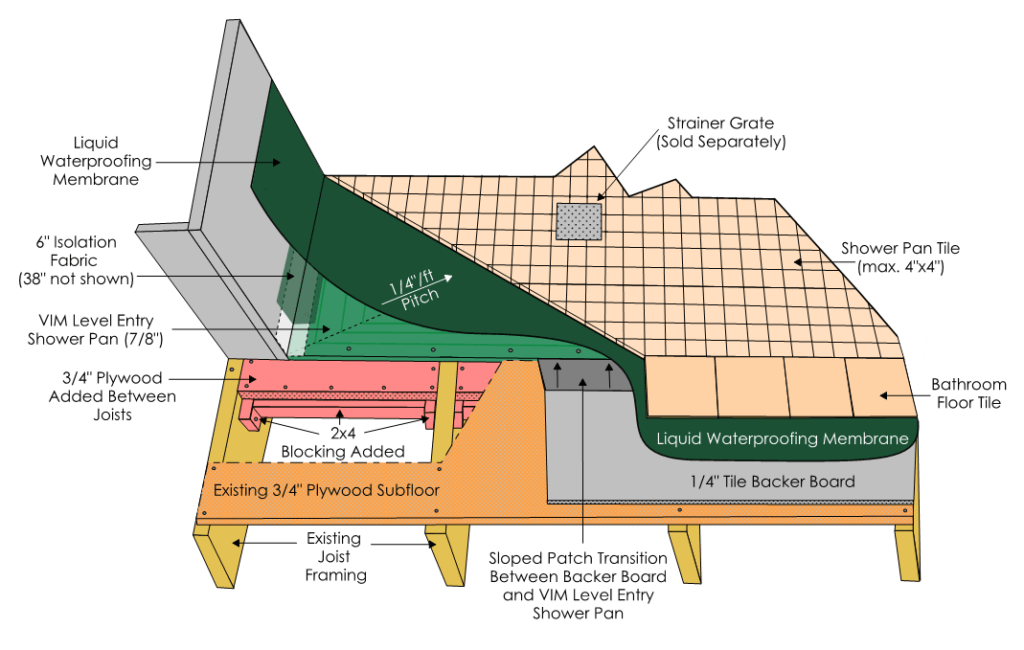

Whether you’re remodeling or building new, a typical shower installation on a wood floor only requires the shower floor area to be recessed ¾”. The final drain connection seal is made from the top side so there’s no need to open the ceiling below the shower area.

CONCRETE FLOOR INSTALLATION

On an existing concrete flooor, a typical 5’x4’ shower installation on an existing concrete floor will only require a cut depth of approx. 1.1/4”. On a new concrete floor, a 5’x4′ installation will only require a stamp-out depth of approx. 1″ in the shower area. In both cases, the final neoprene drain connection seal is made from the top side.

REASONS THE VIM SHOWER is Superior

Anti-Fracture Waterproofing

The liquid waterproofing supplied with our shower system is applied in conjunction with our isolation fabric to create a high-quality, anti-fracture membrane that will give years of trouble free showering.

Durable Shower Pan

The pre-sloped VIM Shower Pan is constructed from recycled ABS plastic, so it's resistant to expansion and contraction. Our 60" x 48" pan is fully customizable and can be field-cut to fit smaller showers, or it can be extended using quick-drying patch compound to fit larger showers.

Superior Drain System

Our drain system is engineered with a series of weep holes to allow any water that penetrates the shower floor tile to quickly drain back into the waste system. This small but effective feature greatly diminishes the opportunity for mold and mildew to form under your tile.

Center Drain Location

Our system accommodates a center drain rather than linear drain location.